Automatic Checkweighers CW-5000

High speed (up to 250 ppm) automatic checkweighers for production lines.

Do you want to know more about Automatic Checkweighers CW-5000?

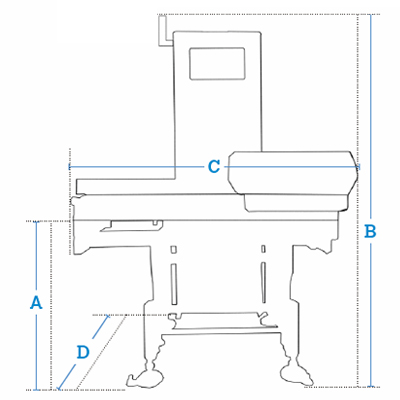

Data in mm

| A | 850 - 950 (adjustable height, minimum height 400 mm +/- 50) |

|---|---|

| B | 1,975 - 2,075 (adjustable height) |

| C | 970 (with L300-L600 conveyors) |

| D | 850 (for W200 conveyors) |

Outstanding functions

- High performance weighing: up to 172 ppm in approved equipment, and up to 250 ppm in non-approved equipment.

- Discrimination by weight checking.

- Productivity control.

- Effective filling control “℮“ (optional).

- MID certification: approved equipment.

- Modular design.

- Ranges from 1.5 kg/ 0.5 g to 15 kg/ 5 g.

- IP65 stainless steel electric drawer.

Weighing

- Weighing type: Dynamic or static.

- Ranges depending on the dimension of the weighing conveyor:

- 1.5 kg / 0.5 g with conveyor of up to L300 x W200 mm.

- 3 kg / 1 g with conveyor of up to L300 x W200 mm.

- 6 kg / 2 g with conveyors of up to L400 x W280 mm, L400 x W400 mm and L600 x W280 mm.

- 15 kg / 5 g with conveyors of up to L600 x W400 mm, L800 x W280 mm and L800 x W400 mm.

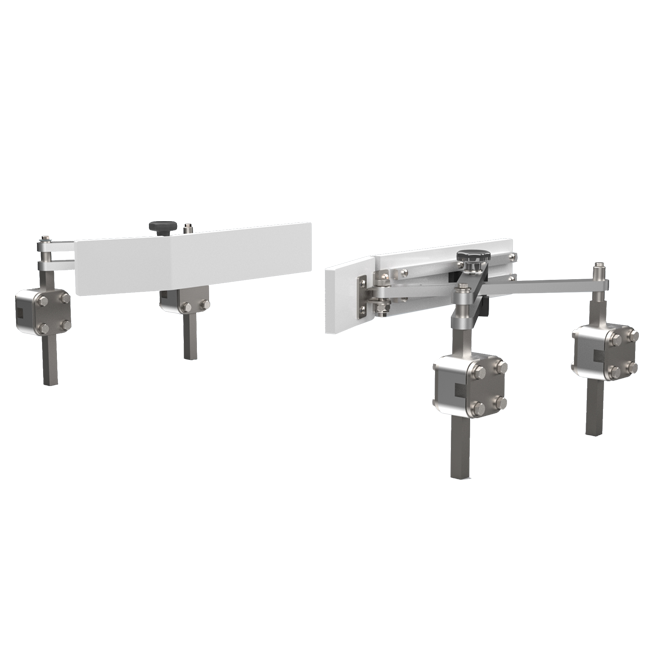

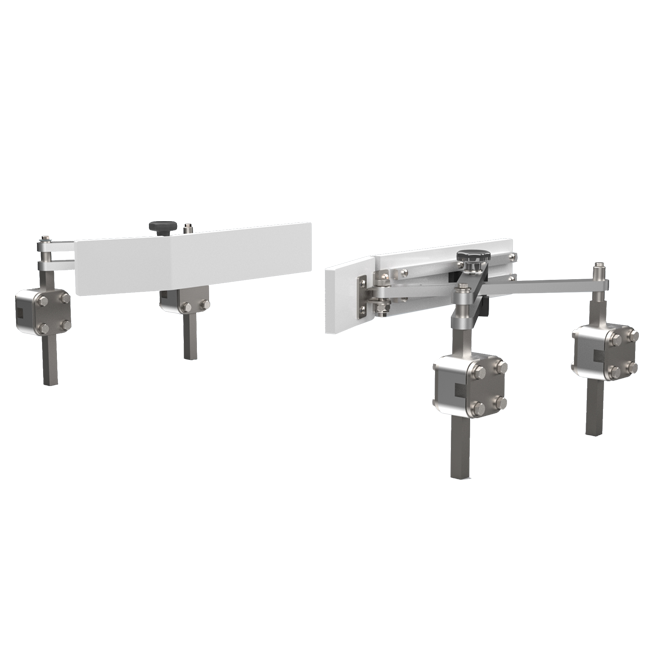

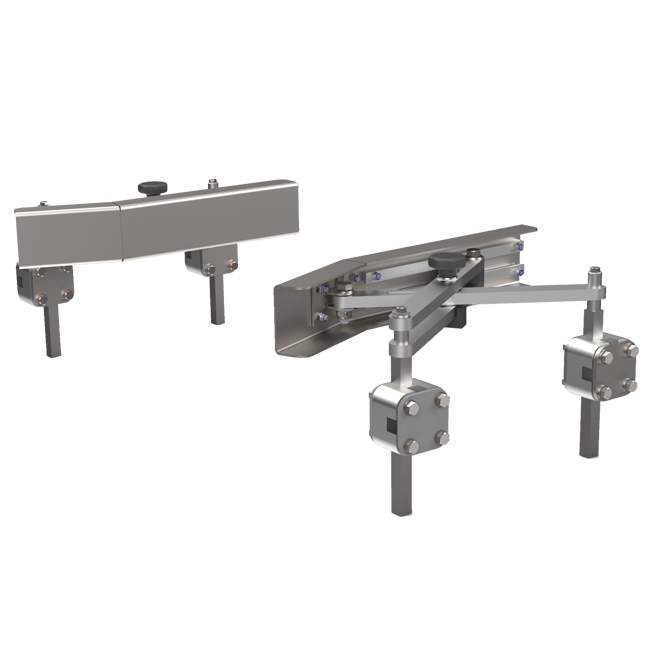

Rejection system (optional)*

- Rejection system type:

- “Air-jet ®” air blowing.

- Pneumatic piston.

- Accompanying blade.

- Pusher blade.

- Number of rejectors and function:

- 1 rejector: weight out of range.

- 2 rejectors: weight above and weight below range.

- Rejector for unprocessed product.

- Rejector for product with metal (necessary connection with metal detector).

* All the rejection systems (pneumatic piston, “Air-jet®”, etc.) depend on the type of product/packaging, required speed, collection system, etc.; please always check with Dibal.

Construction

- Structure: AISI 304L stainless steel and anodized aluminium.

- Belts (all of them with FDA approval):

- Standard.

- High speed: super adherent.

- Sliders: for expulsion areas.

- Guides: AISI 304L stainless steel, anodized aluminum and cestilene.

- TFT 10,1’’ capacitive touch screen (optional TFT 15’’).

- Vertical electric drawer with TFT integrated.

Communications to PC

- Ethernet TCP/IP.

- RS-232.

- 4 USB (3.0).

PC software

- Direct connection to equipment from any device with access to the same same network as the CW-5000 via the Google Chrome browser.

- Data export to Excel or CSV.

Power supply & compressed air

- Electrical: 230 V / 50 Hz.

- Air: max. 150 l/min (at 6-8 bar) (in case of incorporating rejection system).

CW-5000 600/300x200

0 Rejectors

- 1 infeed L600 x W200 mm conveyor and 1 weighing L300 x W200 mm conveyor, with high speed belt.

- For products of up to L200 x W200 mm, and up to 3 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 172 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 250 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

CW-5000 400/400x280

0 Rejectors

- 1 infeed and 1 weighing L400 x W280 mm conveyor, with high speed belt.

- For products of up to L350 x W280 mm, and up to 15 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 162 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 250 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

CW-5000 600/600x280

0 Rejectors

- 1 infeed and 1 weighing L600 x W280 mm conveyor, with high speed belt.

- For products of up to L550 x W280 mm, and up to 15 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 130 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 180 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

CW-5000 600/600x400

0 Rejectors

- 1 infeed and 1 weighing L600 x W400 mm conveyor, with high speed belt.

- For products of up to L550 x W280 mm, and up to 15 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 130 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 180 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

CW-5000 800/800x280

0 Rejectors

- 1 infeed and 1 weighing L800 x W280 mm conveyor, with high speed belt.

- For products of up to L750 x W280 mm, and up to 15 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 100 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 170 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

CW-5000 800/800x400

0 Rejectors

- 1 infeed and 1 weighing L800 x W400 mm conveyor, with high speed belt.

- For products of up to L750 x W400 mm, and up to 15 kg.

- Without rejection system (check for options).

- Horizontal detector.

- Performance*: 100 packages/minute (with products of up to L120 mm and 0.5 kg). In MID conditions (M). Up to 170 packages/minute without approval.

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, the rejection system installed and MID conditions (M).

Stainless steel product guides

Visual and audible alarm (24V)

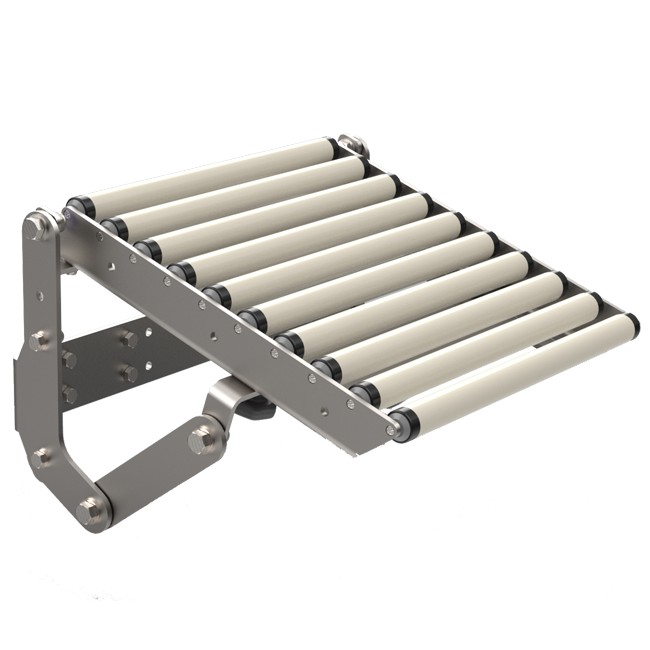

Exit ramp

- W200 mm non-motorized PVC rollers for W200 mm conveyors.

- W280 mm non-motorized PVC rollers for W280 mm conveyors.

- W400 mm non-motorized PVC rollers for W400 mm conveyors.

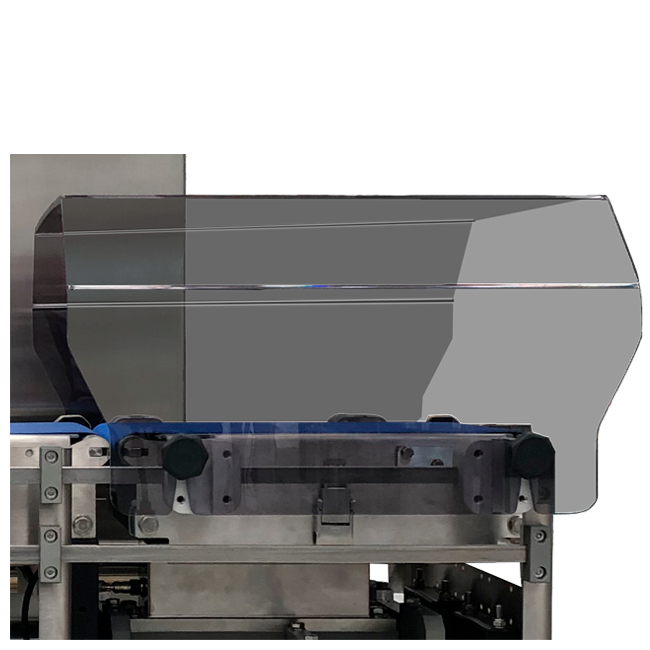

Polycarbonate protector

- L300/ L400/ L600/ L800 x A200 mm weighing conveyor.

- L600/ L800 x A400 mm weighing conveyor.