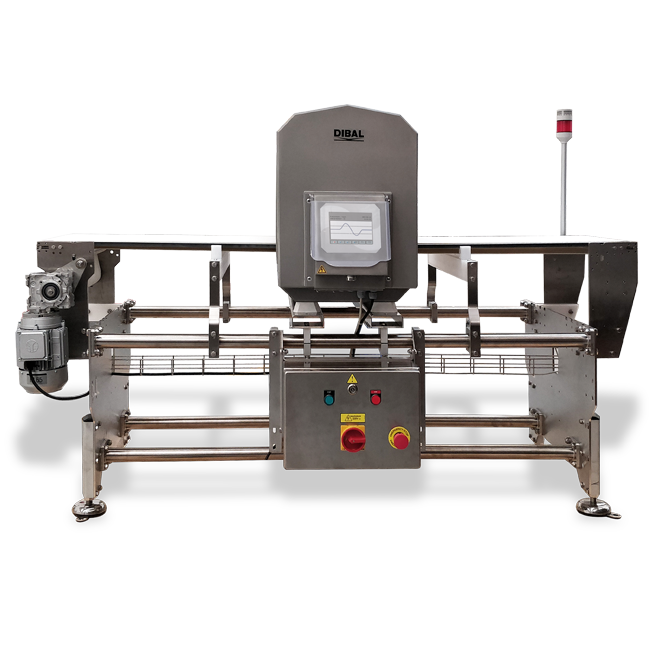

Metal Detectors with Conveyor MD-5700

Multi-frequency product inspection equipment, with arc and conveyor belt, for metal detection in the food industry.

Do you want to know more about Metal Detectors with Conveyor MD-5700?

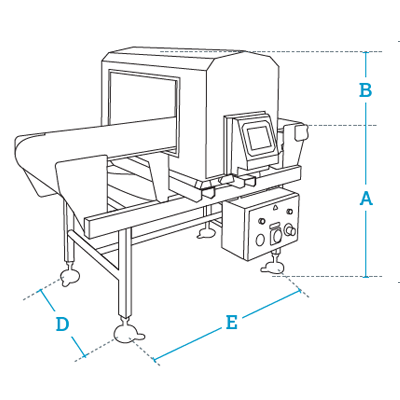

Data in mm

| A | 800 - 950 (adjustable legs) |

|---|---|

| B | 290 |

| C | 1,140 - 1,240 |

| D | 550 |

| E | 1,120 |

Outstanding functions

- Multi-frequency.

- Variable conveyor belt speed.

- “Auto-setup” with inteference suppression and automatic calibration of sensitivity.

- Digital multi-filter: To guarantee maximum stability in harsh environments.

- Auto-balance: Automatic detection and compensation of any signal changes (example: variations in temperature).

- Precise detection area: Exact location of the metal particle in the detection field for easy separation.

- Auto-monitoring: To control the proper working of the equipment.

- Automatic cancellation of product effect, with capacity to measure the product parameters in real time.

- Dynamic self-monitoring (monitoring changes in product characteristics). it guarantees maximum sensitivity in each operation.

- Safety: access protected by three password levels.

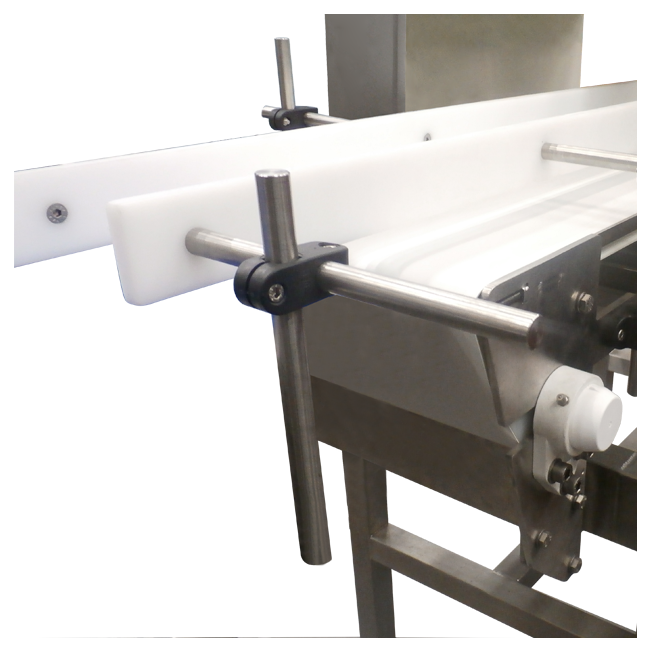

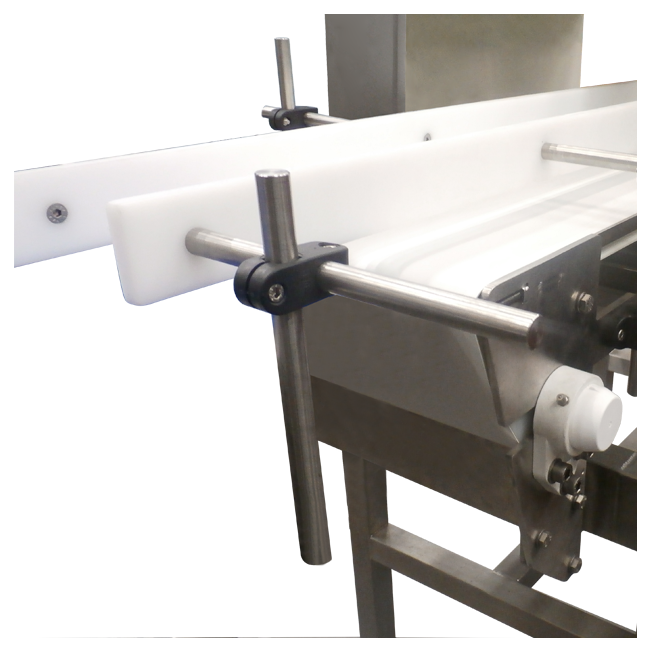

Construction

- Structure:

- AISI 304 stainless steel tunnel, with IP66 protection (IP69K, optional).

- Anodized aluminum frame (AISI 304 stainless steel, optional).

- IP66 protection (IP69K, optional).

- AISI 304 stainless steel electrical box, with IP69 protection.

- Transport conveyor driven by motor with IP55 protection (IP66, optional).

- Belts: Smooth rigid or modular.

- Console: 5.7” colour touch screen (protection cover included).

Complete kit for compliance with IFS / BRC regulations

- Optional; it includes:

- Conveyor length increase.

- Optical rejection sensor + full bucket optical sensor.

- Rejection system.

- Methacrylate protection tunnel.

- Closed with key bucket.

- Visual and audible alarm.

Communications to PC

- RS-232.

- Ethernet.

- Wi-Fi optional.

- USB port: To export reports of detection and changes on configuration, as well as for back up.

Power supply

- 100-240 V AC, 50/60 Hz.

Possible integration with other equipment

- Dibal LS-4500 and CLS-4500 automatic weigh-price labellers.

- Dibal CW-4500 checkweighers.

- Dibal GW-4500 graders.

MD-5700S (1300/200/300/150)

- W200 mm smooth belt.

- Maximum product dimensions:

- Dry product: W200 x H75 mm.

- Moist product: W200 x H50 mm.

- Maximum weight on belt: 15 kg.

MD-5700S (1300/300/400/200)

- W300 mm smooth belt.

- Maximum product dimensions:

- Dry product: W300 x H0125 mm.

- Moist product: W300 x H100 mm.

- Maximum weight on belt: 15 kg.

MD-5700S (1800/400/500/300)

- W400 mm smooth belt.

- Maximum product dimensions:

- Dry product: W400 x H225 mm.

- Moist product: W400 x H200 mm.

- Maximum weight on belt: 15 kg.

MD-5700H (2000/400/500/350)

- W382 mm modular belt.

- Maximum product dimensions:

- Dry product: W400 x H275 mm.

- Moist product: W400 x H250 mm.

- Maximum weight on belt: 50 kg.

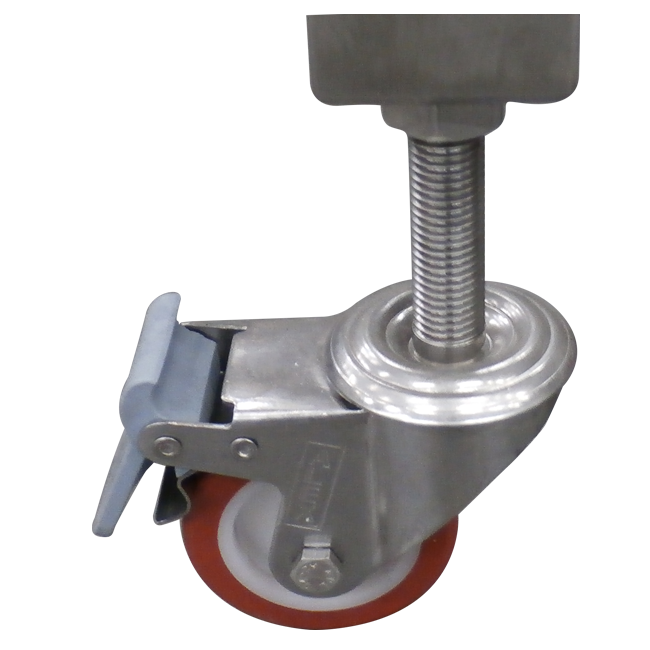

4 wheels with brakes

Stud included.

24V visual and audible alarm

Without IP protection.

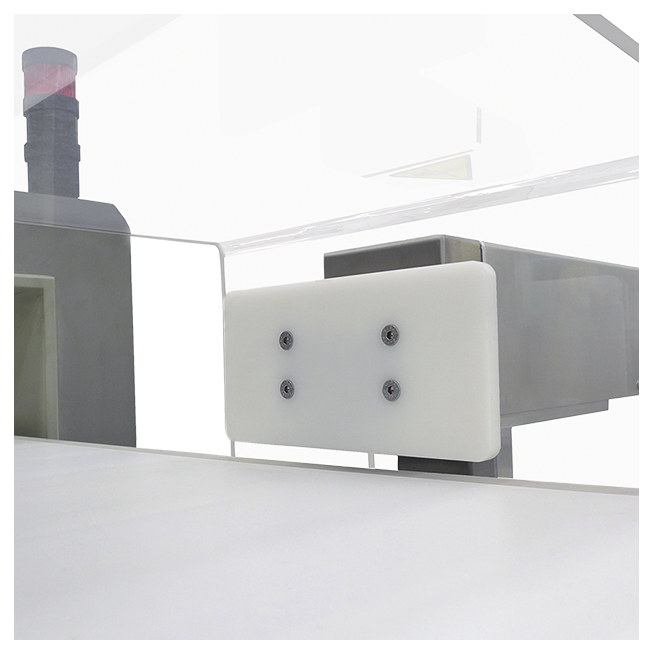

Rejection system

Pneumatic piston, accompanying blade, push blade, air blowing...

Container for contaminated products

Motorised conveyor

Input/output L1,000 x W280 mm conveyor, with smooth belt.

Rollers conveyor

Rollers conveyor for transporting or accumulating products.

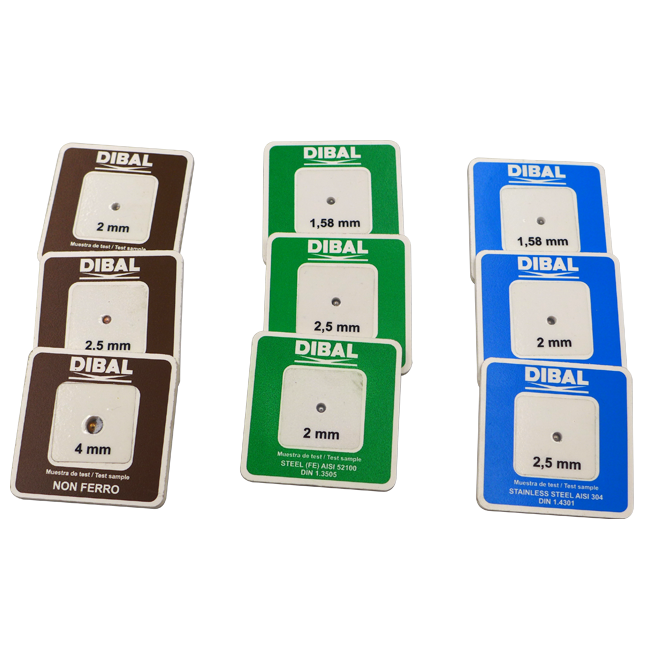

Test card kit

Measurements for model MD-5700S 1300/300/400/200.

For other sizes, contact us.