Pipeline Metal Detectors MDS-5700

Multi-frequency product inspection equipment for metal detection in vacuum fillers in food industry.

Do you want to know more about Pipeline Metal Detectors MDS-5700?

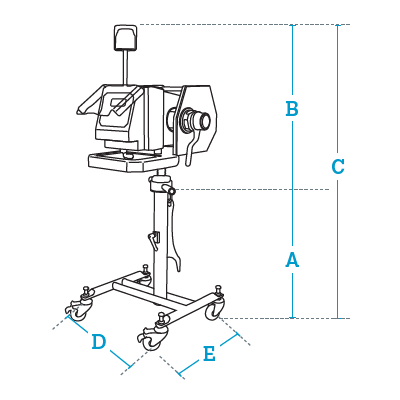

Data in mm

| A | 700-1,055 (adjustable height) |

|---|---|

| B | 550 |

| C | 1,250-1,605 |

| D | 555 |

| E | 590 |

Outstanding functions

- Multi-frequency.

- “Auto-setup” with interference suppression and automatic calibration of sensitivity.

- Digital multi-filter: To guarantee maximum stability in harsh environments.

- Auto-balance: Automatic detection and compensation of signal changes (example: variations in temperature).

- Precise detection area: Exact location of the metal particle in the detection field for easy separation.

- Auto-monitoring: To control the proper working of the equipment.

- Automatic cancellation of product effect, with capacity to measure the product parameters in real time.

- Dynamic self-monitoring (monitoring changes in product characteristics). it guarantees maximum sensitivity in each operation.

- Safety: access protected by three password levels.

Construction

- Structure:

- Stainless steel tunnel.

- Stainless steel frame.

- IP69K protection.

- 4 wheels with brakes included.

- Visual and audible alarm included.

- Console: 5.7” colour touch screen (protector included).

Communications to PC

- RS-232.

- Ethernet.

- Wi-Fi optional.

- USB port: To export reports of detections and changes on configuration, as well as for back up.

Power supply

- 100-240 V AC, 50/60 Hz.

Possible integration with other equipment

- Handtmann vacuum filler (connection flanges included).

- Vemag vacuum filler.

- Handtmann twisting device.

- Others filling equipment, contact us.

MDS-5700 / 60

- Model without connection to devices.

- 60 mm nominal diameter.

MDS-5700R / 60

- Model with transmission to twisting device.

- 60 mm nominal diameter.

MDS-5700V / 60

- Model with reject valve.

- 60 mm nominal diameter.

MDS-5700 / 100

- Model without connection to devices.

- 100 mm nominal diameter.

MDS-5700V / 100

- Model with reject valve.

- 100 mm nominal diameter.