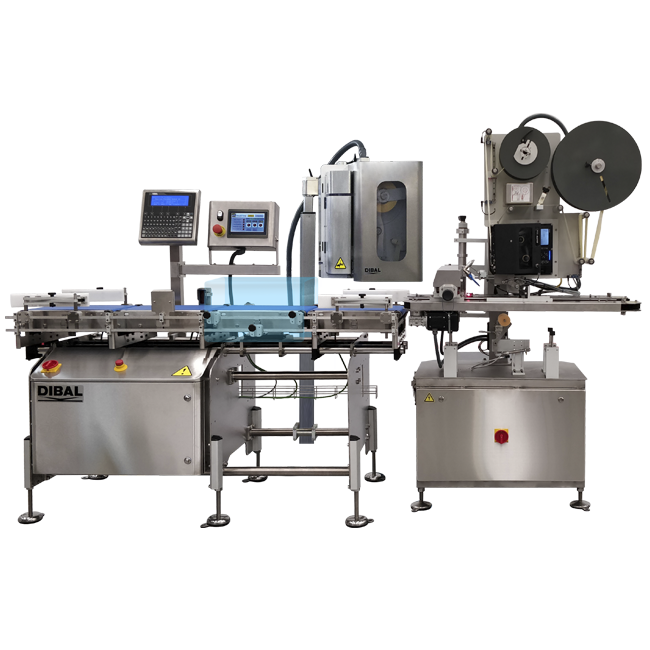

C-Wrap Automatic Labellers CLS-4500

Automatic weighing and C-wrap labelling equiment.

Do you want to know more about C-Wrap Automatic Labellers CLS-4500?

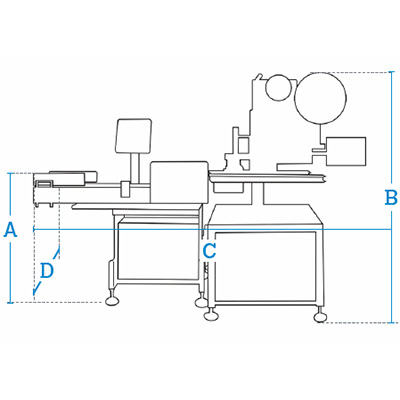

Data in mm

| A | 850 - 950 (adjustable legs) |

|---|---|

| B | 1,750 |

| C | 2,850* |

| D | 1,015 (for W280 conveyors)** |

Main features

- A small-sized unit, which makes it easier to integrate into pre-existing lines.

- Easy to change tray size, which reduces changing times:Allows labels of up to L340 mm.

- Automatic motorized adjustment of the belts, optional.

- Optionally, the equipment is prepared for the upper and / or lower application of labels and for “full wrap” labelling.

- Prints Windows fonts and logos.

Outstanding functions

- Labelling of fix/variable weight/price.

- Discrimination by weight checking.

- Orders management.

- Labelling of totals (3 levels).

- Generic traceability on label.

- Adapted to comply with EU Regulation 1169/2011 referring to food information.

- Barcodes: EAN-8, EAN-13, EAN-128, CODE 128, ITF-14, GS1 Datamatrix and GS1 Databar (up to 4 codes per label).

- Maximum of free texts per article: Up to 30.

- Maximum of logos per label: Up to 999.

- Maximum of fonts: Up to 90 (true type).

- Maximum of label formats: Up to 999.

- Upstream and downstream (connections included).

Weighing

- Weighing type: Dynamic or static.

- Ranges depending on the dimensions of the weighing conveyor:

- 6 kg / 2 g with conveyor of up to L400 x W280 mm.

- 10 kg / 5 g, 3 kg / 1 g or other, contact us.

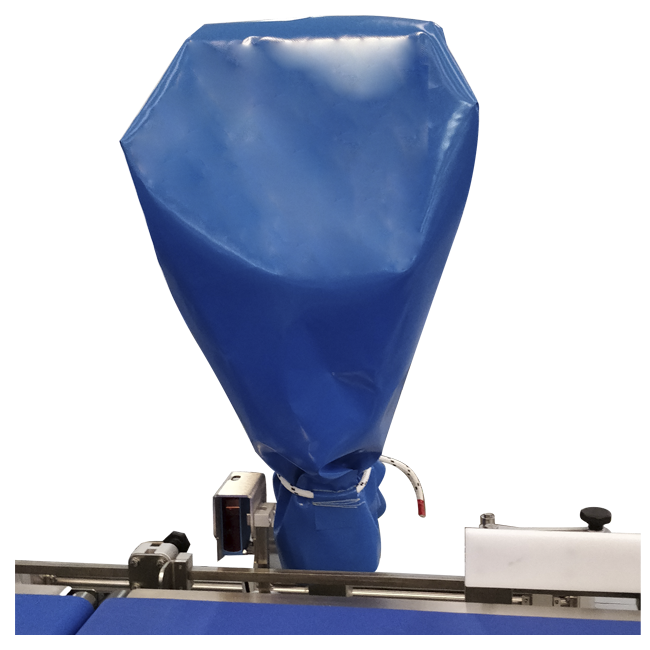

Labelling system

- Printing type:

- C labelling or "full wrap": Thermal Transfer (TT). Ribbon saver, optional.

- Top and/or under labelling: Direct Thermal (DT) or Thermal Transfer (TT).

- Printhead:

- C labelling or "full wrap": Long-lasting 4”.

- Top and/or under labelling: Long-lasting 4”.

- Resolution: 8 dots/mm.

- Printing speed:

- C labelling module: up to 406.4 mm/s.

- Second top labeler and under labeler: up to 250 mm/s.

- Label applicator type:

- C labelling or "full wrap": contact/drag.

- Top labelling: “Air-jet®” (AA) or pneumatic piston, optional.

- Under labelling: contact.

Labels

- Dimensions depending on the inches of the printhead:

- C labelling module:

- C labelling: from W60 x L120 mm, up to W80 x L340 mm.

- "Full wrap": consult us.

- Top labelling: from W60 x L60 mm, up to W80 x L140 mm.

- Top labelling module: from W40 x L40 mm, up to W102 x L120 mm.

- Under labelling module: from W40 x L40 mm, up to W102 x L120 mm.

Construction

- Structure: AISI 304 stainless steel and anodized aluminium.

- Protective cover for C labeller (optional): Stainless steel AISI 304, with protection against water.

- Belts (in sequencing, infeed, weighing and separation conveyors): Polyurethane, rigid or elastic depending on the equipment range, with FDA approval.

- Console:

- Material: stainless steel.

- “Qwerty” keypad and backlit graphic LCD display.

- Guiders: It includes standard product guiders in sequencing and separation conveyors.

Communication to PC

- Ethernet TCP/IP.

PC software

- DIS: For equipment configuration, production data management and back up (LBS).

- DLD: for graphic design of labels.

- Integration tools: see section on software.

Power supply & compressed air

- Electrical: 230 V y 50 Hz.

- Air: max. 150 l/min (at 6-8 bar).

Energy consumption

- 1,25 kW.

Possible integration with other equipment

- Dibal LP-3000 manual weigh-price labeller (for labels of totals).

- Dibal GS-3000 batch collector (+ LP-3000, for labels of totals).

- Dibal MD-5000 metal detector.

- ZPL protocol printers.

CLS-4500

- 1 sequencing conveyor, 1 infeed conveyor, 1 weighing conveyor (with polycarbonate protector) and 1 separation conveyor of L400 x W280 mm.

- For products from L80 x W80 x H40 mm up to L300 x W280 x H100 mm (for other dimensions, consult us).

- 1 C labeller, thermal transfer printing, 4” printhead and label applicator by contact/drag.

- Performance* in MID conditions (M):

- 60 labels/minute (with labels of W60 x L320 mm, and products of up to L200 mm and 2 kg).

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, dimensions and characteristics of the label, and MID conditions (M).

CLS-4500 Top

- 1 sequencing conveyor, 1 infeed conveyor, 1 weighing conveyor (with polycarbonate protector) of L400 x W280 mm and 1 labelling conveyor of L800 x W280 mm.

- For products of from L80 x W80 x H40 mm up to L300 x W280 x H100 mm (for other dimensions, consult us).

- 1 top labeller, direct thermal printing, 4” printhead and label applicator by piston.

- 1 C labeller, thermal transfer printing, 4” printhead and label applicator by contact/drag, with 1 exit conveyor of L400 x W280 mm.

- Water protection kit: protected engines, bearings with lock, packaging gland, special load cell and heated detector, and protective cover for C labelling system.

- Performance* in MID conditions (M):

- 80 labels/minute in top labeller (with labels of W60 x L320 mm, and products of up to L200 mm and 2 kg).

- 60 labels/minute in C labeller (with labels of W60 x L320 mm, and products of up to L200 mm and 2 kg).

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, dimensions and characteristics of the label, and MID conditions (M).

CLS-4500 Under

- 1 sequencing conveyor, 1 infeed conveyor, 1 weighing conveyor (with polycarbonate protector) of L400 x W280 mm and 1 under labelling conveyor of L600 x W280 mm and another of L400 x W280 mm.

- For products of from L80 x W80 x H40 mm up to L300 x W280 x H100 mm (for other dimensions, consult us).

- 1 under labeller, direct thermal printing, 4” printhead and label applicator by contact.

- 1 C labeller, thermal transfer printing, 4” printhead and label applicator by contact/drag.

- Performance* in MID conditions (M):

- 80 labels/minute in under labeller (with labels of W60 x L60 mm, and products of up to L200 mm and 2 kg)

- 60 labels/minute in C labeller (with labels of W60 x L320 mm, and products of up to L200 mm and 2 kg).

* Maximum performance will depend on the size, weight and morphology of the product, as well as on the regularity of the infeed of the products, dimensions and characteristics of the label, and MID conditions (M).

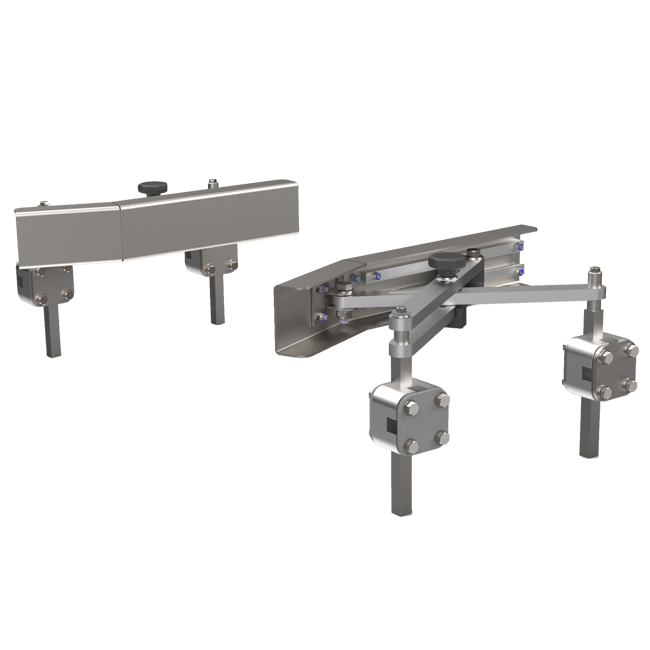

Stainless steel guides

(to replace cestilene guides)

* These measurements correspond to the sum of the sequencing, infeed, weighing, separation and C labelling conveyors in and exit conveyors in CLS-4500 model. For other sizes, contact us.

** For other sizes, contact us.