Automatic Checkweighers CW-5000

High speed (up to 250 ppm) automatic checkweighers for production lines.

Automatic high speed weigh-price labellers: up to 200 packages per minute.

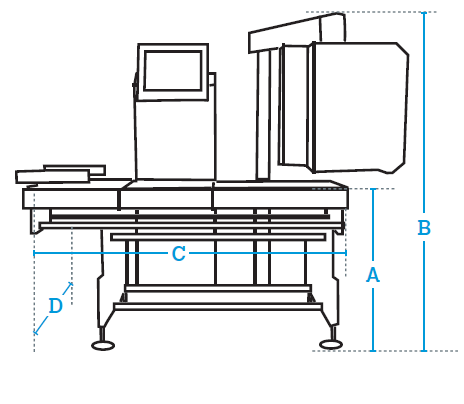

| A | 750 - 850 (adjustable height) |

|---|---|

| B | 1,550 - 1,850 (adjustable height) |

| C | 1,526 (with L400-L400-L600 conveyors)* |

| D | 595 (conveyors width + console width. For W280 conveyors)** |

* These measurements correspond to the sum of the separation, infeed, weighing and labelling conveyors.

For other sizes, contacts us.

** For other sizes, contact us.